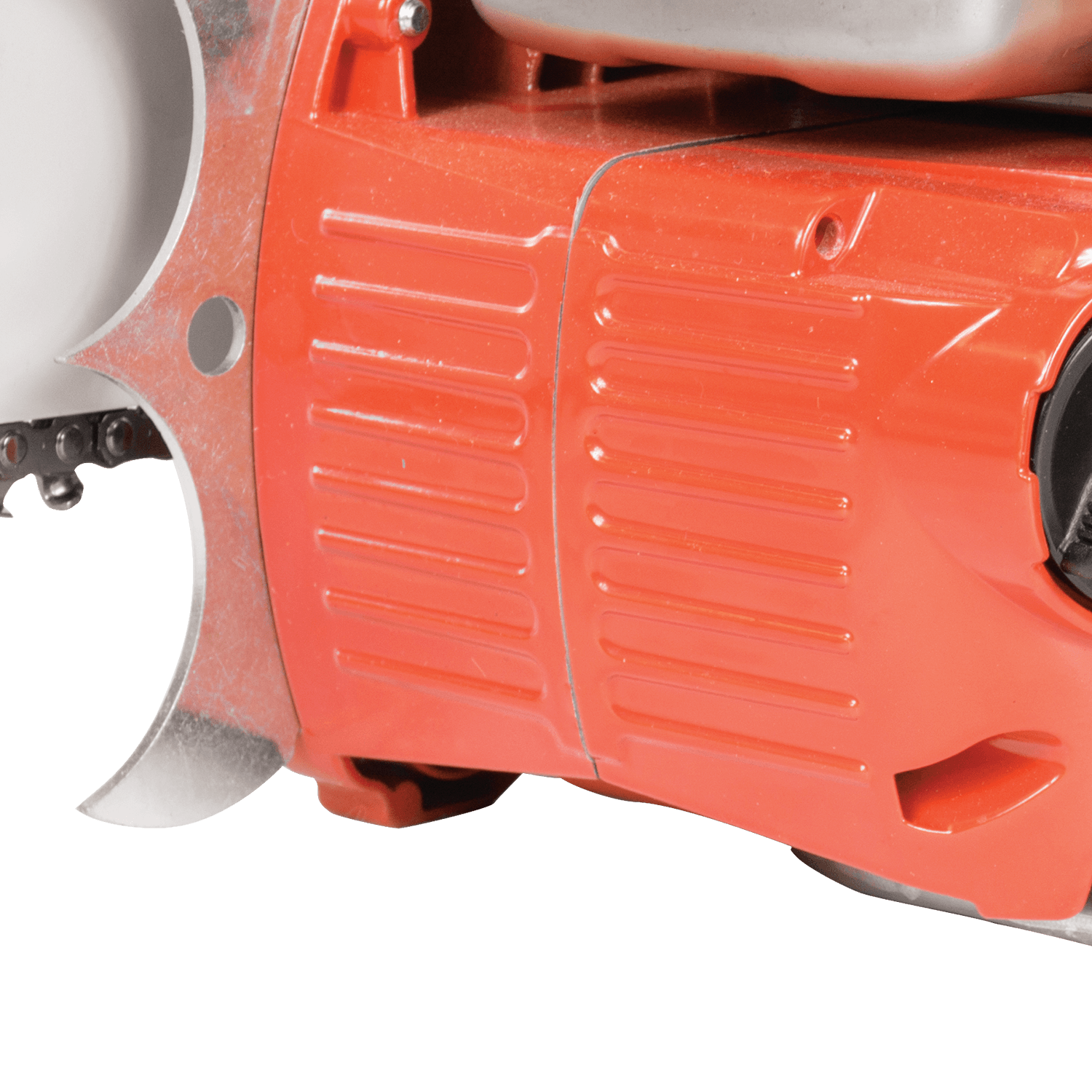

Diamond blades contain industrial-grade diamond embedded in segments or rims on their cutting edge. As the blade is used, the abrasive qualities of the material being cut (such as concrete) wears down the segment. Diamond crystals either get crushed or let loose as the metal matrix gets worn away, exposing new diamonds to continue the cutting. The abrasive quality of the material being cut is a large factor in choosing the correct blade for a job. Harder, less abrasive materials such as cured concrete require a blade with a softer metal mix to ensure adequate erosion of the segment brings new diamond to the surface at an optimum rate. Soft, abrasive materials such as green concrete and asphalt tend to wear down segments faster. Therefore, segments with a harder, more wear-resistant metal mix in the segment, provide longer blade life and overall better performance. Segments come in different heights. The total segment height is not as important as the diamond depth – the portion of the segment that contains diamonds. The diamond depth combined with diamond concentration and quality determines the overall performance value of the blade.

••• FINANCING NOW AVAILABLE ON EQUIPMENT •••

Product page

NED 12" x .125 x 1"/20mm DP LDH-500 AMERICAN MADE General Purpose Blade 100500LH1203

Call For Pricing

Email: sales@easyequipmentsales.com

Locations: 20 South Ave, Lewiston, ME 04240 | 587 Main Street, Gorham, ME 04038

© 2026

All Rights Reserved | Easy Equipment Sales & Service • Built by ADvantage Media